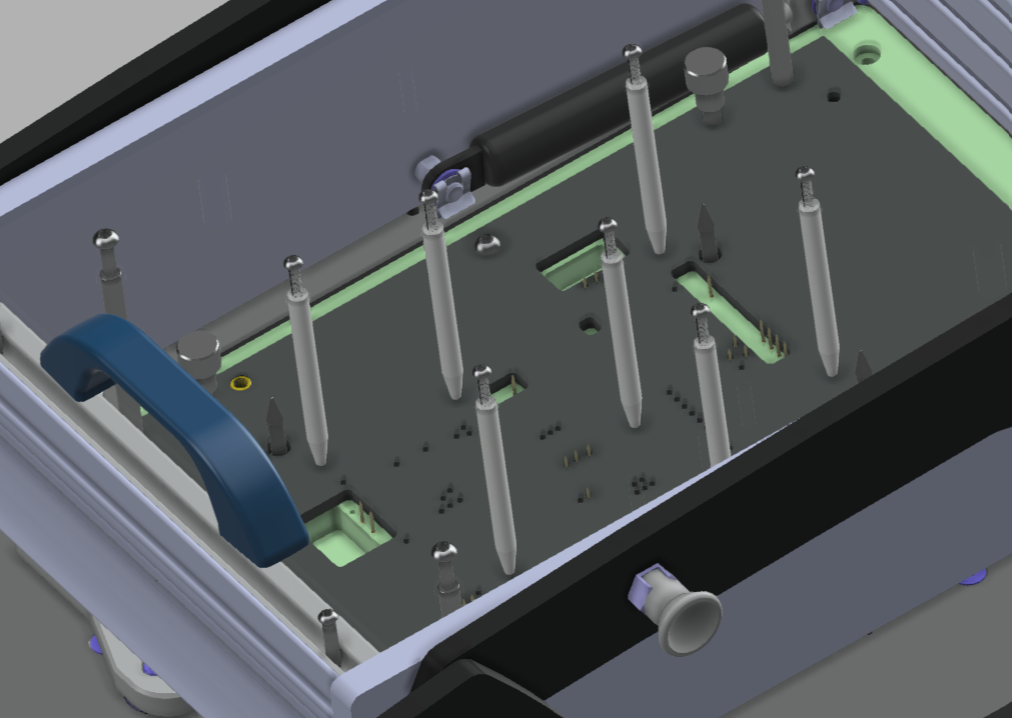

Pressure Application

Our test fixtures use two primary methods for applying pressure to PCBs: Pressure Pins and Pressure Application Pads. Pressure Pins are the standard choice for rigid PCBs, while Pressure Application Pads are used for specialized applications like flex PCBAs or high-density boards where space is limited.

Pressure Pins

Pressure pins provide controlled downward force on the DUT (Device Under Test), ensuring reliable contact with the test probes below.

These precision-machined components are manufactured from durable engineering plastics:

- Acetal (Delrin)

- POM (Polyoxymethylene)

Pin lengths are standardized across our fixture families:

- 35mm length

- Used in Dev Pro and Dev Pro XL fixtures

- 45mm length

- Used in Dev and Dev XL fixtures

- 65mm length

- Used in all Ingun cartridges and fixtures

For Ingun fixtures specifically, we incorporate a 7mm diameter countersink that's 3.2mm deep in the pressure plate. This accommodates standard 6mm diameter pressure pins while providing optimal force distribution for 1.6mm thick PCBs.

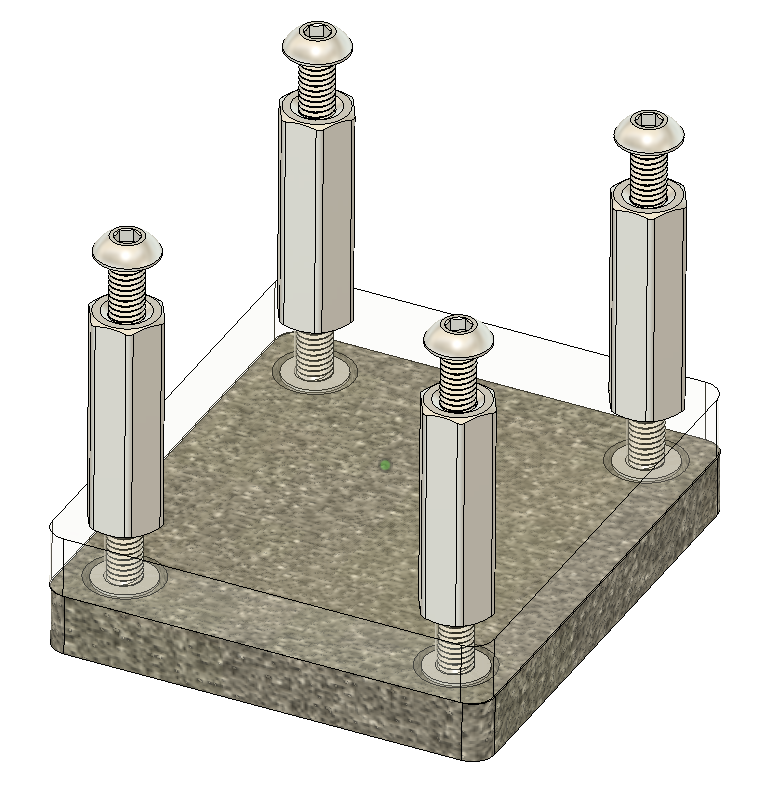

Pressure Application Pad

The Pressure Application Pad system combines a rigid plate (polycarbonate or acrylic) with a compliant polyethylene pad. This assembly provides even pressure distribution, making it ideal for:

- Flex and rigid-flex PCBAs

- High-density PCBAs where traditional pressure pins cannot fit

- Applications requiring gentler, more distributed force

The pad assembly mounts securely to the pressure plate using M3 or M4 standoffs, ensuring consistent pressure application across the entire test area.