Dev-Pro Fixture Design Guidelines

This page provides best practices and component recommendations for building reliable Dev-Pro series test fixtures. Follow these guidelines to ensure optimal performance, ease of assembly, and cost-effectiveness.

Recommended Components

Guide Pins

- GP-2TL guide pins are the preferred method for accurately locating the DUT (Device Under Test) within the fixture.

- If the DUT's locating holes are smaller than 3mm (minimum 2.5mm), use a custom cradle for positioning.

- Cradles should be mounted to GP-2TL guide pins using M3 screws for secure and repeatable placement.

Pressure Pins

- Use 35mm pressure pins for all Dev-Pro fixtures.

- Pressure pins are attached to the pressure plate with M3 x 10mm screws, providing consistent downward force on the DUT.

Receptacles and Probes

- Centalic PQ50/PQ100/PE75 probes and the corresponding RQ50/RQ1200/RE75 receptacles are recommended for Dev-Pro fixtures.

- Probe tip selection:

- Use "B" tips for standard test points.

- Use "A" tips for populated through-hole connections.

- Star type probes from Ingun are also supported for specialized applications.

Fixture Assembly Instructions

DUT Mating Height

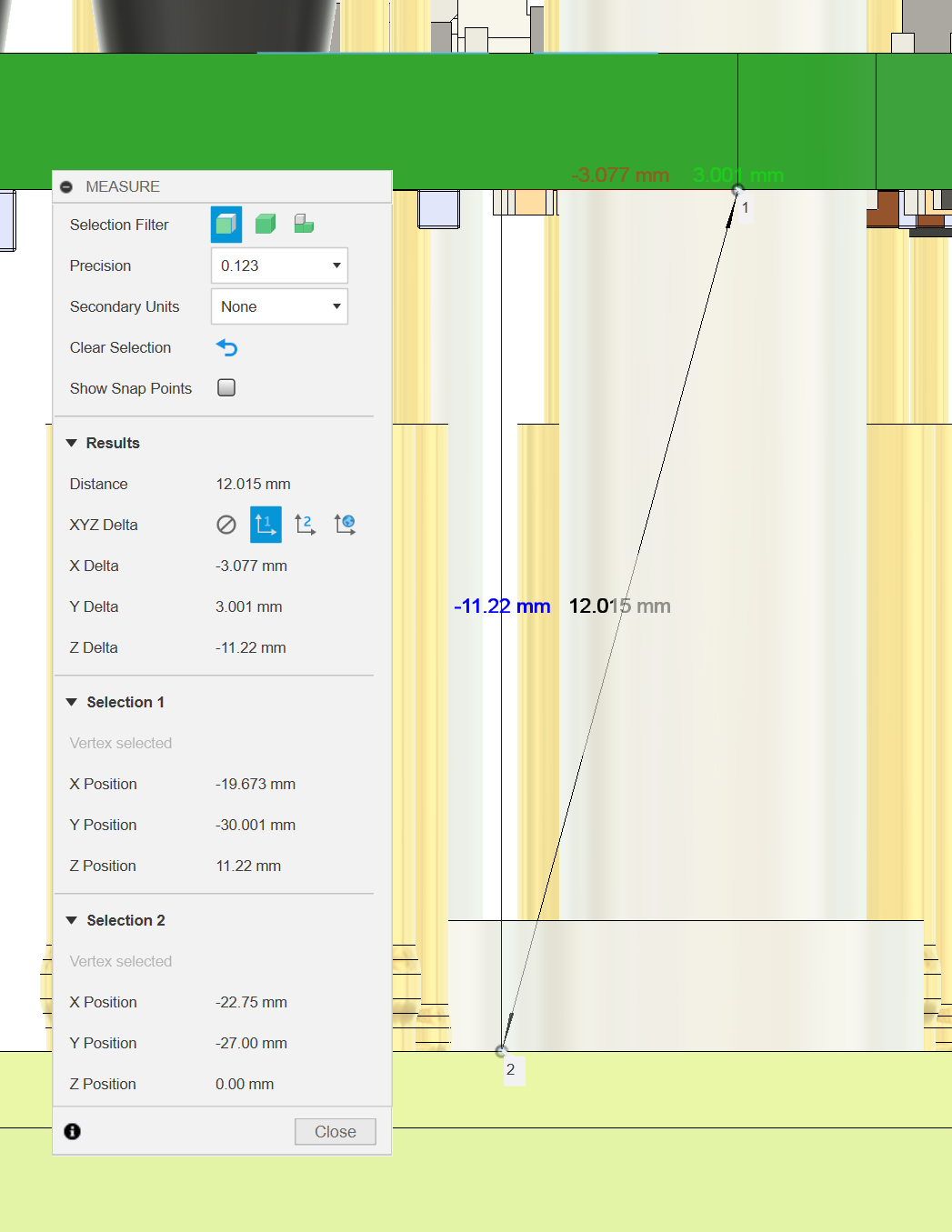

- Position the DUT so that its bottom surface is 11.22mm Z offset to place the DUT at the "working stroke" when the fixture is closed.

- The working stroke positioning ensures optimal probe contact and pressure distribution across the DUT.

- Use a mounting or tooling hole on the DUT for precise and repeatable alignment.

Key Differences from Dev Fixtures

- Guide Pins: GP-2UL instead of GP-2U

- Pressure Pins: 35mm instead of 45mm

- Receptacles/Probes: Centalic PQ50/PQ100/PE75 series instead of generic options

- DUT Height: ~11mm above probe plate (vs 3.5mm for Dev fixtures)

By following these recommendations, you can achieve robust, repeatable, and high-performance Dev-Pro fixture assemblies optimized for professional testing applications.