Test Fixture Maintenance

Test fixtures are critical components in the quality assurance process for PCBAs and other electronic assemblies. Like other sophisticated equipment, test fixtures require regular maintenance to perform their best. FixturFab's recommended maintenance periods are shown below.

Periodic Tasks

Check and Replace Test Probes

The spring-loaded test probes are subject to very different loads. A reliable signal transmission is only possible with fully functional test probes. Conditions for reliable contact are:

- no contamination on the plunger tip

- no excessive wear of the points of the plunger tip

- no scratches on the test probe's plunger shaft

- no metal chips, particles, or other contamination on the probe plate between the probes

- test probe is installed securely in the receptacle

- no height differences between test probes of the same type

- no bending of the test probe

- correct position of the respective test probe types

The spring-loaded test probes can be removed and installed quickly without the need additional wiring thanks to the receptacles. Specialized insertion and extract tools are available from INGUN to replace test probes.

Cleaning Test Probes

Test probes can be cleaned with commercially available, soft plastic or glass fibre brush or cleaning mats to remove severe contamination.

CAUTION

📢 High radial forces can lead to deformation of the probe. Ensure no side forces act on the test probes during the cleaning process!

- Note the plating wear

- Manual cleaning of the test probe plunger tips has a slightly abrasive effect on the outer plating

Repeated cleaning of tips can lead to removal of the conductive plating, which impairs the electrical performance. However, keeping plunger tips free from contamination will ultimately ensure reliable test results and improve the life expectancy of the probe.

Remove loosened dirt particles from the working area using vacuum or suction after cleaning

Cleaning the Test Fixture

Clean the test fixture with a soft cloth and a mild detergent. For cleaning, do not use cleaners with solvent or acidic content.

Grease/Lubricate the Test Fixture

Maintenance-free floating bearings and permanently lubricated deep groove bearings are installed in the test adapter to ensure that maintenance work is not required for these bearing components. The cam tracks of the rear bearing blocks are greased. Long-term testing under full loads show clearly that re-lubrication of these cam tracks is not required.

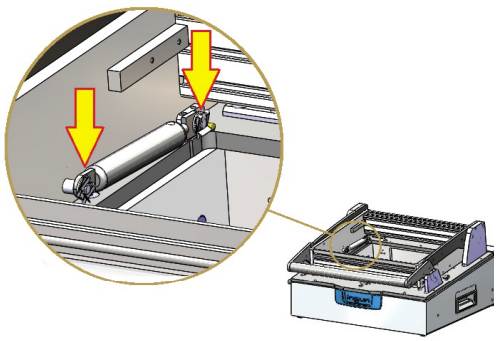

The gas pressure spring bearings (see picture below) should be serviced with a drop of sewing machine oil every 50,000 strokes.

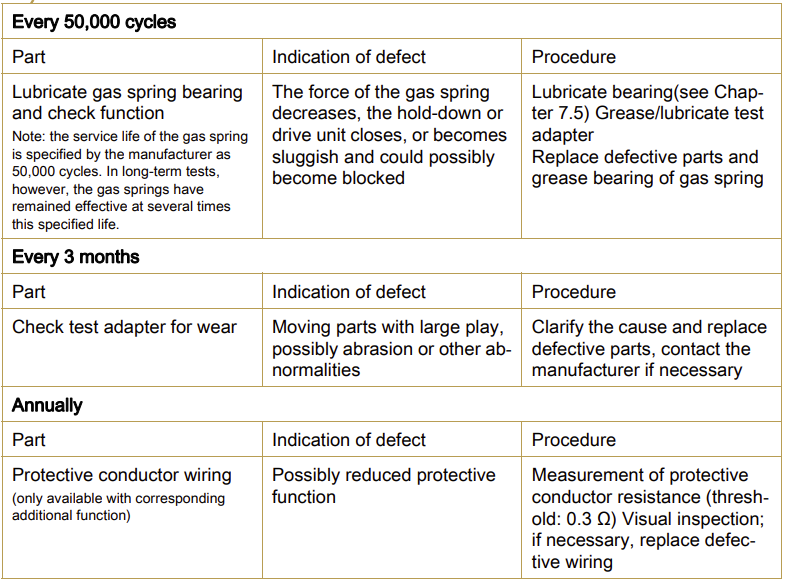

Ingun Fixture Base Maintenance

The recommended maintenance periods for Ingun Test Fixture Bases is shown in the image below.

Ingun Spare Parts

Spare parts for all Ingun Test Fixture Bases and Cartridges can be found in Ingun Spare Parts Catalog.

For specific parts (probes, guide pins, etc.) to service your fixture, see the maintenance manual provided within the Design Package of the Test Fixture or System design.