Fixture Switches

Fixture switches are used to detect when the pressure frame is closed on a test fixture, ensuring that the Device Under Test (DUT) is properly seated and that the test probes are making adequate contact before testing begins. These switches provide a critical safety and quality control function by preventing test execution when the fixture is not properly closed.

The type of switch used varies depending on the fixture type and application requirements, balancing factors such as cost, cycle life, reliability, and safety requirements.

Switch Types

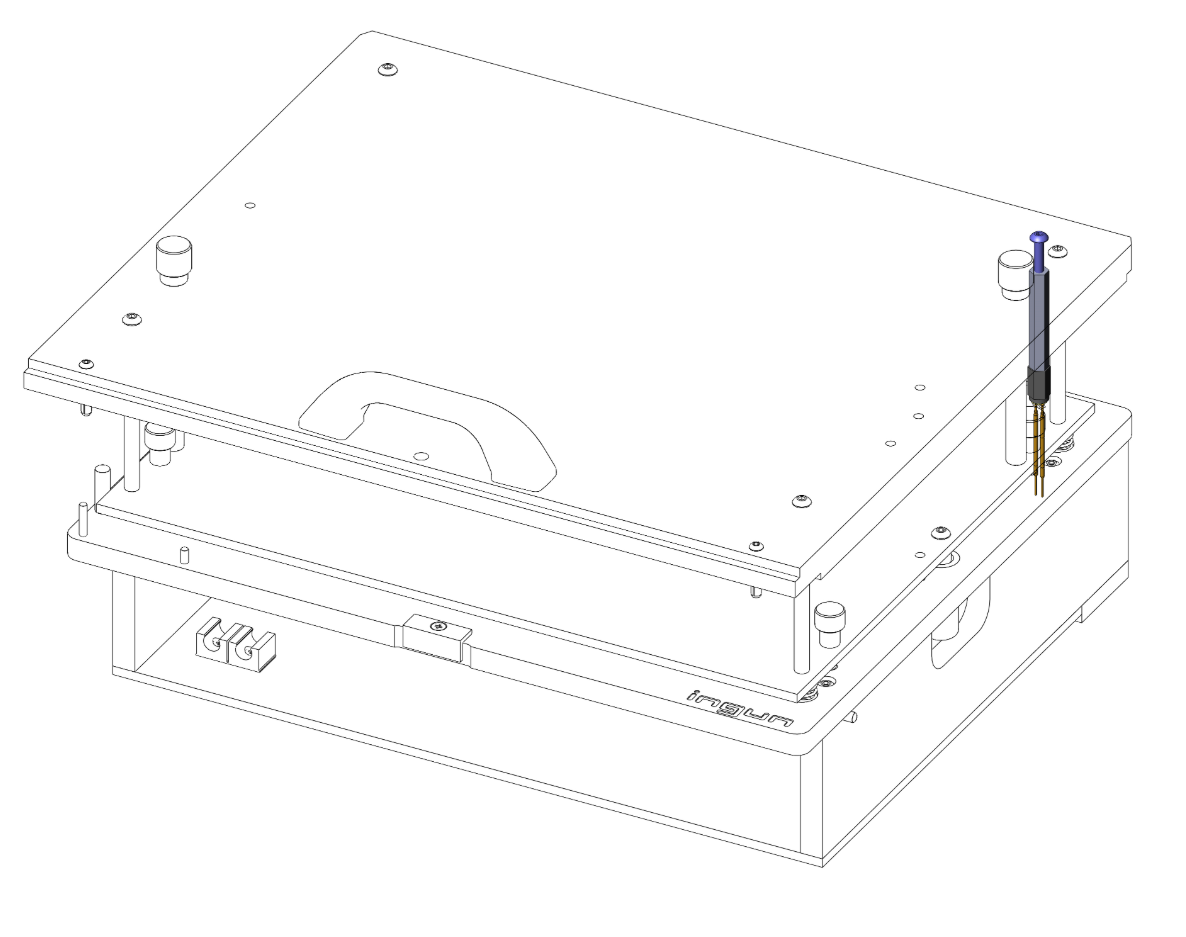

Dev Fixture Switch

For Development and Development Pro fixtures, we use End-Stop Switches that provide both Normally Closed (NC) and Normally Open (NO) contacts. These switches are actuated when the pressure frame reaches the end of its travel, indicating that the fixture is fully closed.

Key Characteristics:

- Dual contact configuration (NC and NO)

- Physical actuation mechanism

- Cost-effective for lower-volume testing

- Easy to install and troubleshoot

- Suitable for prototype and development environments

Pinout

The switch features 3 connections offering both Normally Closed (NC) and Normally Open (NO) contacts. The pins are labelled as follows:

- S: Common Connection

- G: Normally Closed Connection

- V: Normally Opened Connection

We commonly connect a logic high voltage to the S connection, and then read the G connection using a GPIO with a 10kOhm Pull-Down resistor connected.

Connector and Cable

The End-Stop PCB has a JST XHP-3 connector. When purchased with a Dev or Dev Pro Test Fixture, a 18" long cable with mating JST XHP-3 plugs on both ends is included.

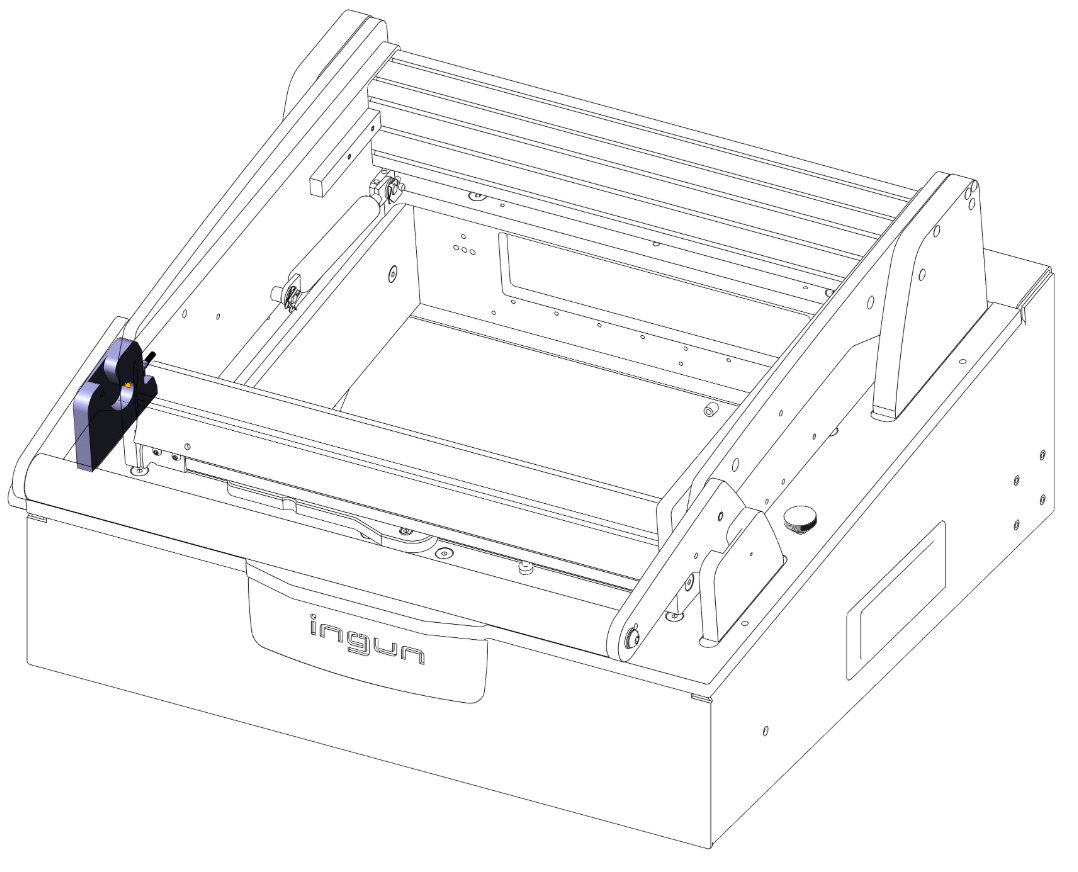

Probe Switches

Probe switches use a simple and cost-effective approach by leveraging the existing probe plate infrastructure. Two test probes are mounted to the probe plate, and a shorting plate (conductive plate) is mounted to the pressure plate. When the pressure plate closes, the shorting plate makes contact with both probes, creating an electrical short circuit that can be detected by the test system.

Advantages:

- Very low cost (uses standard test probes and simple metal plate)

- Easy to implement on existing fixtures

- No additional mechanical switches required

- Can be positioned anywhere on the fixture

- Uses existing probe mounting technology

- Simple to troubleshoot and replace

Considerations:

- Requires two probe positions on the fixture

- Shorting plate must be properly aligned and mounted

- Contact resistance may vary with contact force

- May require cleaning if oxidation occurs on contact surfaces

- Probes must be monitored for wear like other test probes

- Not inherently safety-rated like dedicated safety switches

Implementation Notes:

- Use spring-loaded test probes with adequate travel

- Shorting plate should be made of conductive material (brass, copper, or stainless steel)

- Ensure sufficient contact force for reliable connection

- Route probe signals to a continuity detection circuit in the test controller

- Consider using gold-plated probes for improved contact reliability

- Position probes away from DUT test points to avoid interference

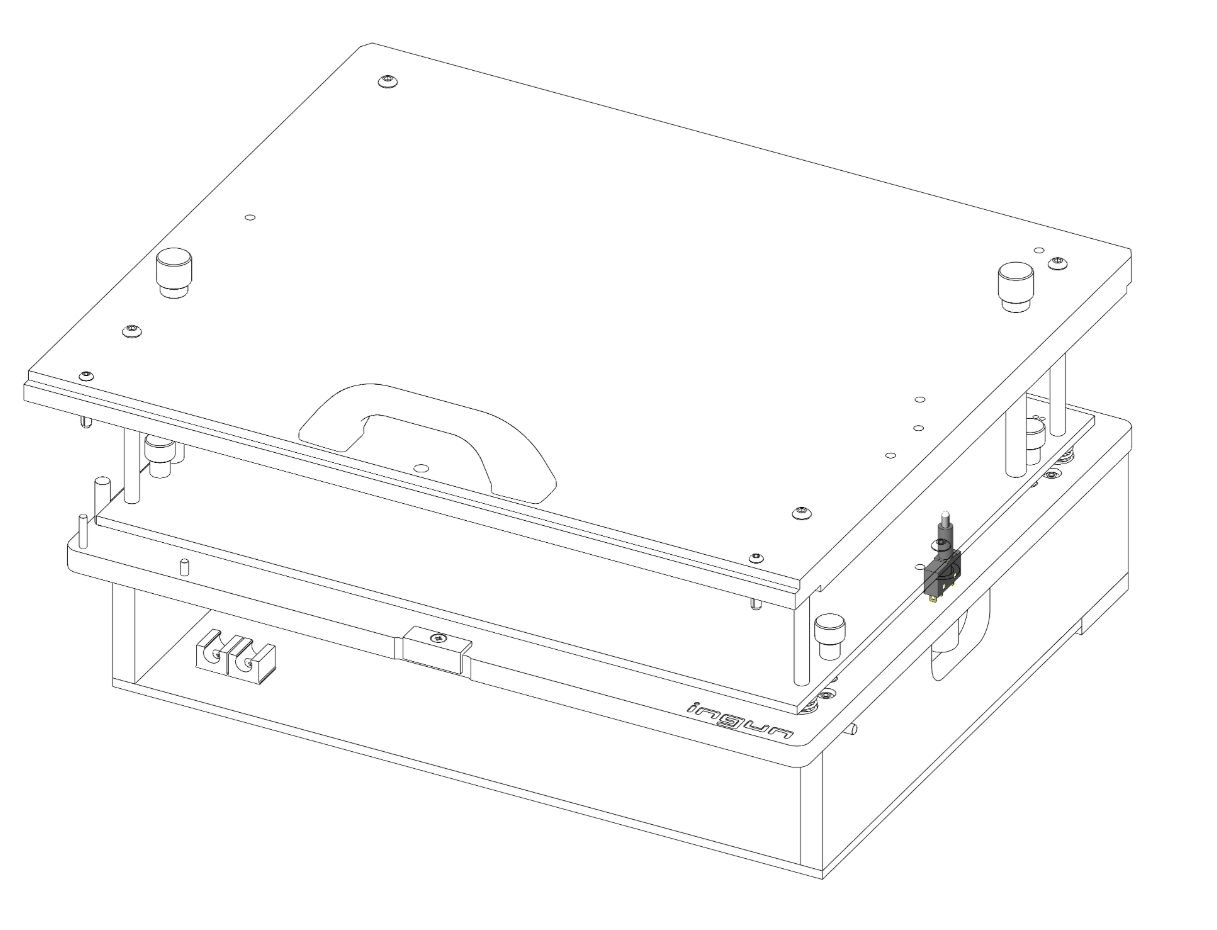

Stroke Switches

Stroke switches operate similarly to end-stop switches but are designed for higher cycle life and more demanding applications.

Advantages:

- Similar operation to end-stop switches

- Higher cycle life than standard end-stop switches

- Available with various actuation forces

- Both NC and NO contacts available

Considerations:

- Mechanical wear over time

- Requires periodic inspection

- May need replacement after extended use

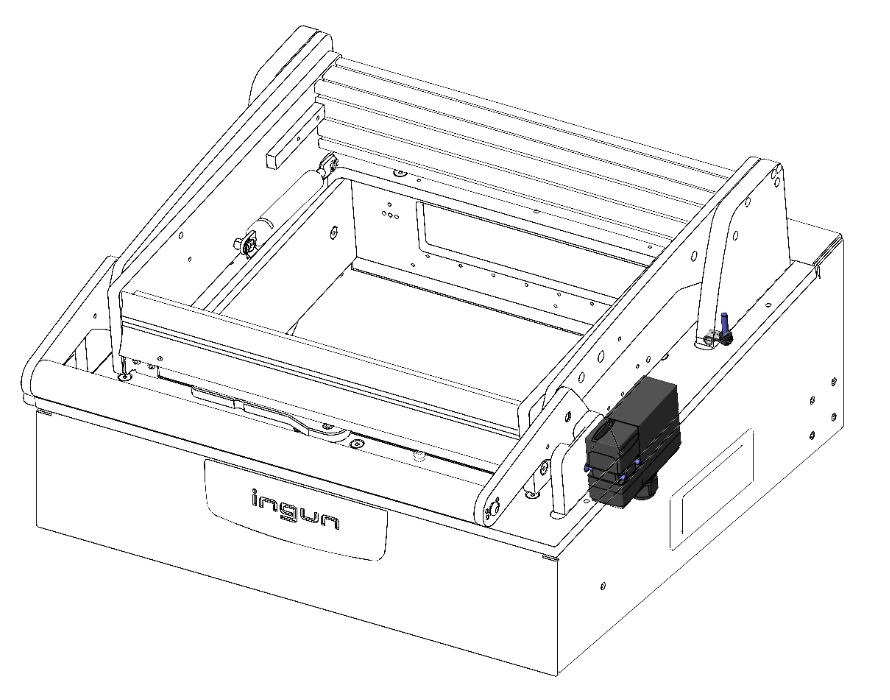

Inductive Switches

Inductive switches use electromagnetic fields to detect the presence of a metal target without requiring physical contact. This makes them ideal for high-cycle production environments.

Advantages:

- No physical contact required

- Higher cycle life (millions of cycles)

- No mechanical wear

- Consistent switching performance over time

- Resistant to vibration and shock

Considerations:

Higher initial cost

Requires proper target material and spacing

May require calibration during installation

Safety Switches

Safety switches provide an additional level of security and can feature interlocking mechanisms to prevent accidental fixture opening during test execution. These are available in both NC and NO configurations.

Advantages:

- Enhanced safety features

- Interlock capability prevents accidental opening

- Meets safety standards for production environments

- Can be integrated with emergency stop systems

- Both NC and NO contact configurations

Considerations:

- Higher cost than standard switches

- May require specific mounting arrangements

- Integration with safety systems may be required

Contact Configuration

Normally Closed (NC)

In an NC configuration, the switch contacts are closed (conducting) when the fixture is open and open (non-conducting) when the fixture is closed. This configuration is often preferred for safety applications because a broken wire or failed switch will prevent testing.

Normally Open (NO)

In an NO configuration, the switch contacts are open (non-conducting) when the fixture is open and closed (conducting) when the fixture is closed. This configuration is intuitive and commonly used for simple presence detection.

Integration Considerations

When implementing fixture switches, consider the following:

- Signal Routing: Switch signals should be routed to the test controller or instrumentation system

- Debouncing: Mechanical switches may require debouncing in software or hardware

- Redundancy: Critical applications may benefit from dual switches for reliability

- Maintenance: Regular inspection and testing of switches is recommended

- Replacement: Keep spare switches on hand for quick replacement if needed

Best Practices

- Always verify switch operation before starting production testing

- Use NC contacts for safety-critical applications

- Consider inductive switches for high-volume production (>100,000 cycles)

- Document switch type and configuration in fixture documentation

- Include switch testing in fixture validation procedures

- Regular maintenance schedules should include switch inspection