DUT Presence Detection

Overview

DUT (Device Under Test) presence detection is a critical safety and operational feature in test fixtures. It ensures that a device is properly loaded before testing begins, preventing damage to both the fixture and the DUT. This is typically implemented using switching probes that detect physical contact with the DUT.

How Switching Probes Work

Switching probes are electromechanical devices that act as normally open (NO) switches. When the plunger is activated by contact with the DUT, the electrical circuit closes, signaling that the device is present. The plunger can be pushed further beyond the switching point, allowing for proper DUT positioning while maintaining the electrical connection.

Key Characteristics

- Normally Open (NO): Circuit is open when no DUT is present

- Closer Type: Circuit closes when plunger is activated

- Over-travel: Plunger can be pushed beyond switching point

- Current Rating: Only transmits rated current when closed

Electrical Connections

The electrical connection between the switching probe and test system can be made using several methods:

- Direct Soldering: Wires soldered directly to receptacle and probe

- Plug Connection: Using standardized connectors

- Quick-Exchange Receptacle: For easy probe replacement

Switching Probe Types

Generic Switching Probe - KG-300K Series

Use Case: Development and prototyping fixtures

Cost: Low-cost solution

Installation: Press-fit into receptacle

Components:

- Solder Tab: Connects to the inner barrel of the switching probe

- Receptacle: Connects to the outer barrel and mounts to Probe Plate or Test Point Carrier Board

- Switching Probe: Inserts into receptacle with solder tab pressed onto bottom connection

Specifications:

- Type: Press-fit installation

- Connection: Direct solder tab connection

- Adjustability: Fixed height, adjustable via 3D Printed Tips

- Maintenance: Requires desoldering for replacement

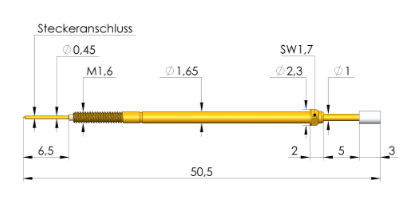

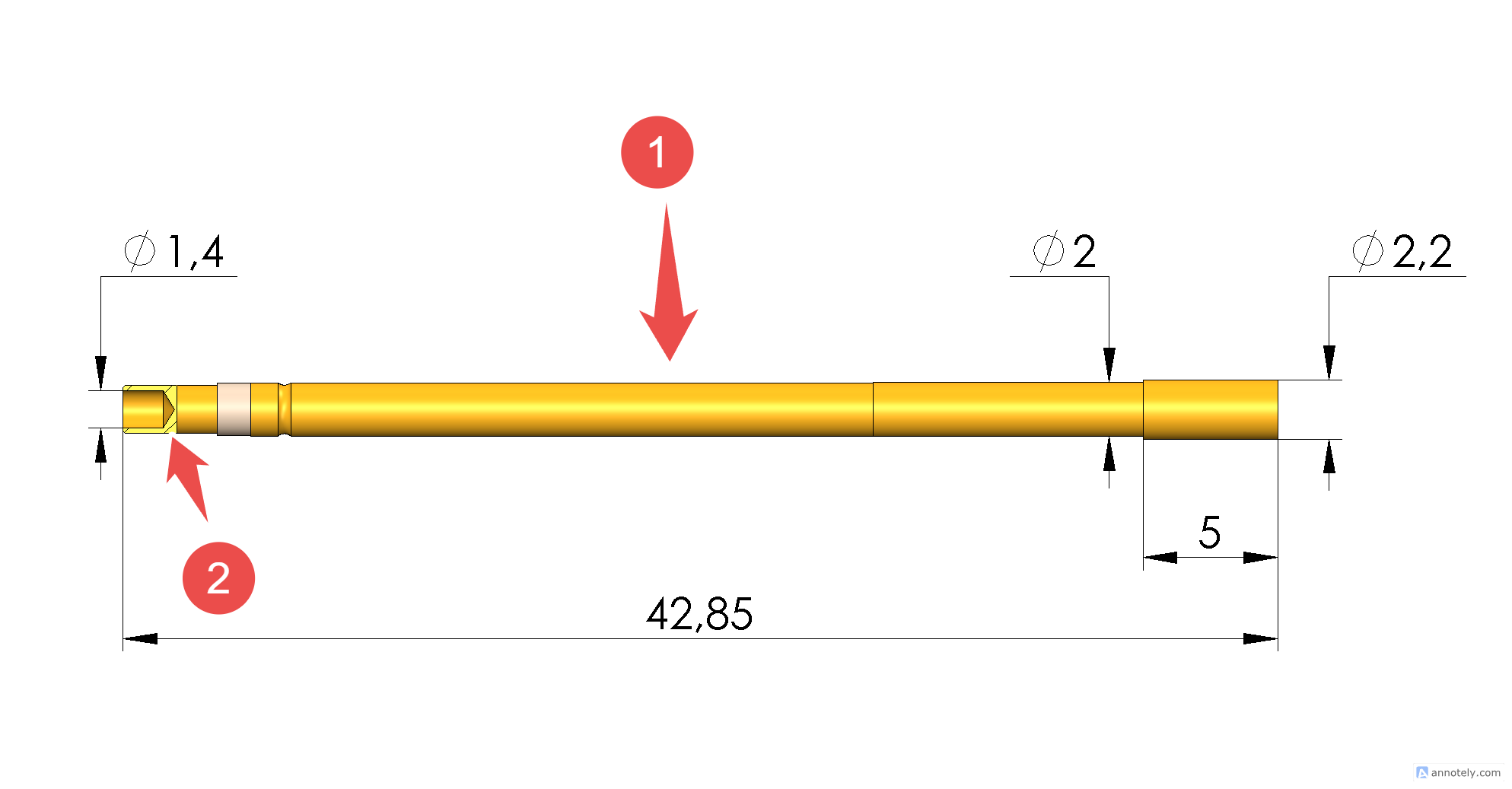

Ingun Switching Probe - SKS-215 MF Series

Use Case: Production fixtures

Cost: Higher cost, professional grade

Installation: Screw-in type with adjustable height

Components:

- Solder Connection 1: Connects to the inner barrel of the switching probe

- Receptacle Connection 2: Connects to the outer barrel of the switching probe

- Switching Probe: Screws into receptacle with adjustable height

Specifications:

- Type: Screw-in installation

- Connection: Dual solder connection points

- Adjustability: Height adjustable by screwing in/out

- Maintenance: Easy replacement without desoldering

Installation Guidelines

Mounting Considerations

- Probe Plate: Mount receptacles securely to prevent movement

- Test Point Carrier Board: Ensure proper electrical isolation

- Height Adjustment: Set switching point for reliable DUT detection

- Wire Routing: Use appropriate gauge wire for current requirements

Electrical Requirements

- Voltage Rating: Ensure probe voltage rating exceeds test voltage

- Current Rating: Match probe current rating to test requirements

- Contact Resistance: Consider impact on low-resistance measurements

- Debounce: Implement software debouncing for reliable detection

Troubleshooting

Common Issues

False Positive Detection

- Cause: Probe stuck in closed position

- Solution: Check for mechanical binding or contamination

- Prevention: Regular cleaning and inspection

False Negative Detection

- Cause: Probe not making contact with DUT

- Solution: Adjust probe height or check DUT positioning

- Prevention: Proper height calibration during setup

Intermittent Detection

- Cause: Loose connections or worn probe

- Solution: Check solder joints and probe condition

- Prevention: Regular maintenance schedule

Maintenance Schedule

- Daily: Visual inspection for damage

- Weekly: Check electrical continuity

- Monthly: Clean probe tips and receptacles

- Quarterly: Replace worn probes

Application Note: TPCB Integration

Switching Probe Implementation on Test Point Carrier Board (TPCB)

When implementing DUT presence detection on a Test Point Carrier Board (TPCB), switching probes require specific footprint design and electrical connections.

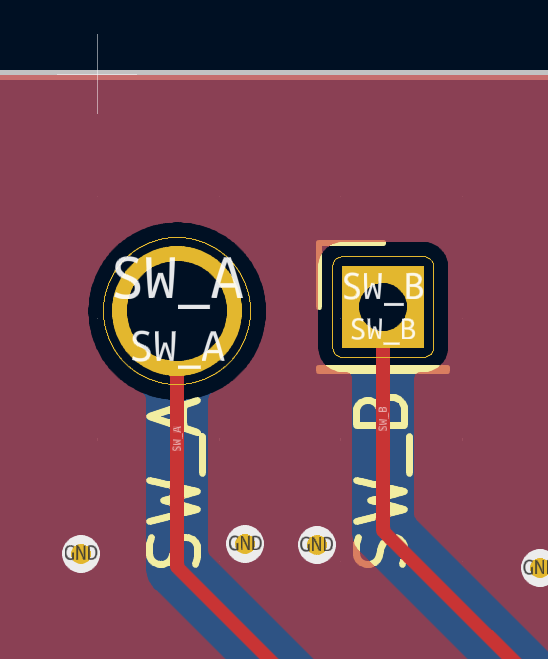

TPCB Footprint Design

The switching probe receptacle requires two separate pads on the TPCB:

- Main Pad: Through-hole pad for the receptacle to be inserted and soldered

- Secondary Pad: Additional pad for wire connection to the secondary contact

Electrical Connection Implementation

Circuit Configuration:

- Normally Open Switch: Probe acts as NO switch when no DUT is present

- Pull-up Resistor: One side pulled to logic high (VCC)

- Digital Input: Other side connected to Digital I/O pin with internal pull-down

Wiring Example:

VCC ----[Pull-up Resistor]---- Probe Contact 1

|

|

Digital I/O Pin (with internal pull-down) ---- Probe Contact 2Probe and Receptacle Components

Switching Probe: Plastic tip that actuates mechanical switch when plunger is pressed

Receptacle: Two-contact design with plastic separation between contacts

Design Considerations

- Pad Spacing: Ensure adequate spacing between main and secondary pads

- Wire Routing: Plan wire routing from secondary pad to avoid interference

- Ground Plane: Consider ground plane clearance around switching probe areas

- Via Placement: Avoid vias under probe mounting areas

- Test Points: Include test points for troubleshooting switching probe operation