Cradles

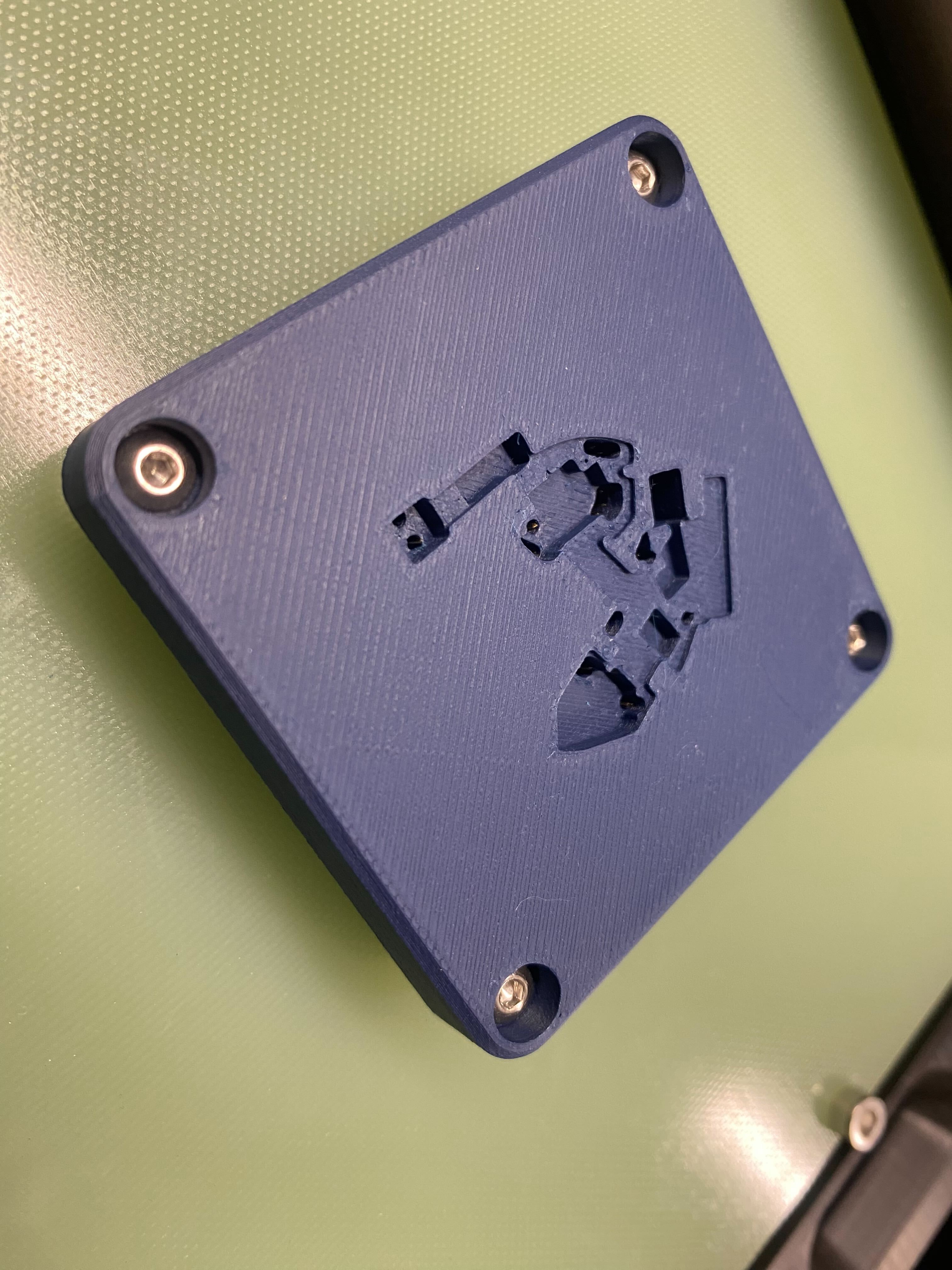

If a DUT doesn't have mounting or tooling holes, a cradle can be used to help locate the DUT within a fixture. Cradles are typically 3D printed from PETG or PLA plastic, or machined from Acetal (Delrin). Below is an example of a 3D printed cradle.

Common Design Parameters

| Parameter | Description | Value |

|---|---|---|

| Cradle Thickness | The thickness of the cradle, measured from the bottom of the fixture to the top of the DUT. | 10mm |

| Min Cradle Offset - Machined | The minimum distance from the bottom of the fixture to the bottom of the DUT. | 0.1mm |

| Min Cradle Offset - V-Groove | The minimum distance from the bottom of the fixture to the bottom of the DUT. | 0.2mm |

| Probe Hole Diameter | The diameter of the probe tip clearance hole. | probe_tip_diameter + 1mm |

| Guide Pin Clearance Hole Diameter | The diameter of the clearance hole for the guide pin. | guide_pin_diameter + 1mm |

Design Tips

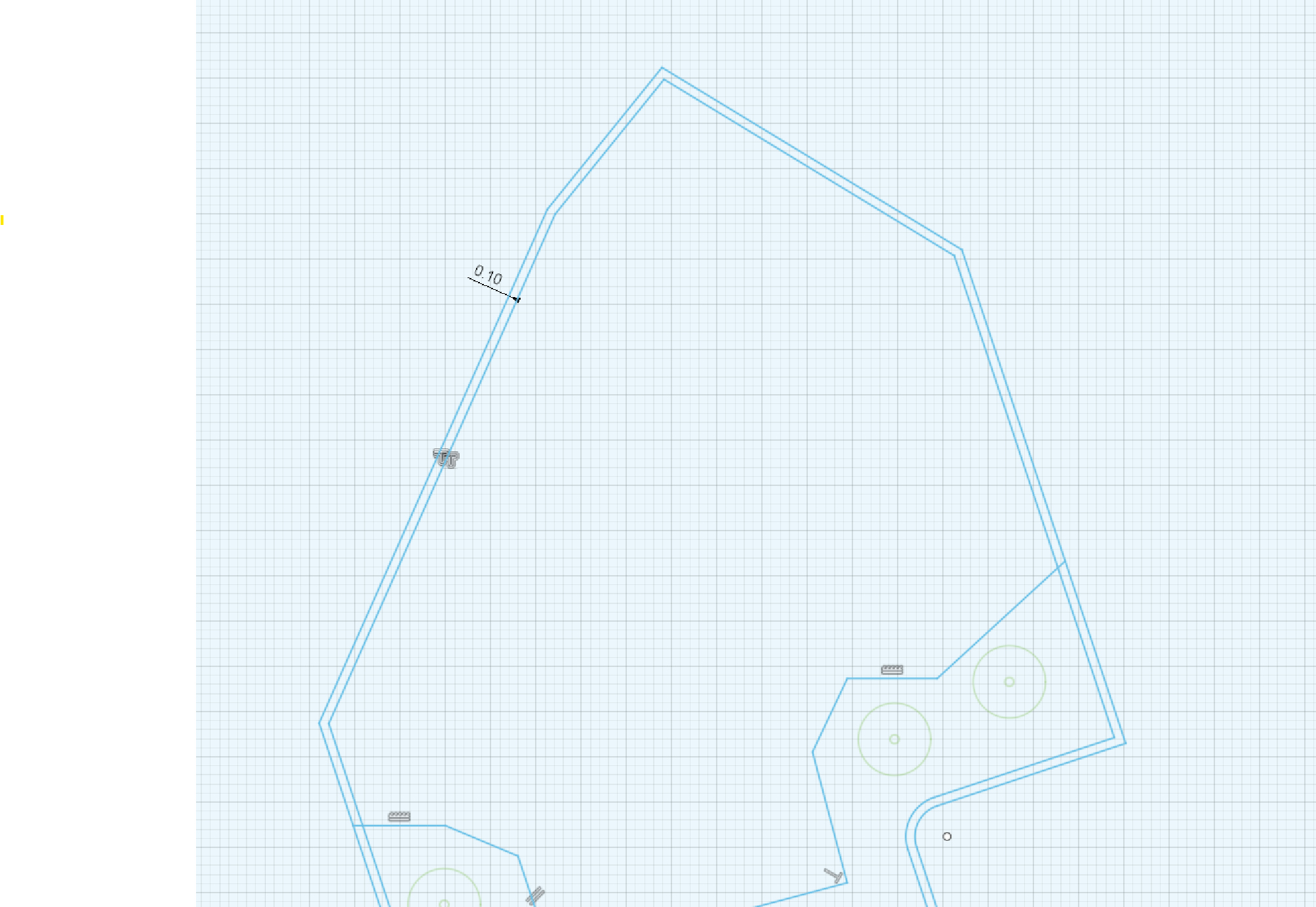

- Use either a STEP model of the DUT, or a DXF file of the PCB outline. These can then be used to create an offset path of the DUT.

- Know the PCBs manufacturing process.

- If the PCB is machined, a 0.1mm offset can be used

- If the PCB is V-grooved, a minimum offset of 0.2mm is recommended.

- The probe hole diameter should be the probe tip diameter + 1mm.

- If a guide pin is mounted to the Probe Plate, a clearance hole should be added to the cradle to allow the guide pin to pass through.

- The clearance hole should be the guide pin diameter + 1mm.

- Chamfer the edges of the cradle to help guide the DUT into place.

Pre-Centering Guides

Pre-centering guides are used to help center the DUT within the fixture. They are typically 3D printed from PETG or PLA plastic, or machined from Acetal (Delrin).

These will typically only cover a portion of the DUT, and will be mounted to the fixture using a screws. In the example above the guide is mounted using M3 screws from the bottom of the moving plate. Make sure to add a chamfer to the edges of the guide to help guide the DUT into place. This should make it easy to align the DUT so that the guide pins are easily located.